Feima Robotics Wins First Prize in the Advanced Category of the Oilfield Inspection Challenge at the 2025 Digital China Innovation Competition!

Recently, the Advanced Category of the Oilfield Inspection Challenge—part of the 2025 Digital China Innovation Competition (Low-Altitude Economy Track), hosted by the Organizing Committee of the 8th Digital China Summit and guided by the National Information Center—was held at the Nanliang General Airport in Huachi, Qingyang, Gansu Province. Feima Robotics was invited to participate with its V10R drone. After several intense rounds of competition, the Feima V10R stood out among many elite UAVs, winning first prize in the advanced category thanks to its outstanding communication technology, advanced situational awareness, and high-precision reconnaissance capabilities.

Champion Performance! Feima Robotics Claims First Place in the Oilfield Inspection Challenge (Advanced Category)

The Oilfield Inspection Challenge is a key component of the 2025 Digital China Innovation Competition’s Low-Altitude Economy Track. It focuses on UAV applications in long-distance pipeline patrols and site facility inspections. The competition featured two levels—standard and advanced—designed to assess route planning, intelligent obstacle avoidance, data collection, and analytical capabilities in complex environments.

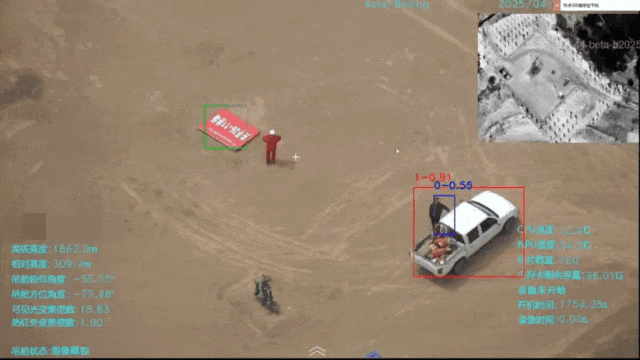

In the advanced category, the task simulated scenarios in the Huachi Oilfield. UAVs were required to conduct a long-endurance inspection over roughly 45 km of complex terrain. Competitors needed to locate people and vehicles near designated coordinates while simultaneously collecting visible and infrared thermal imaging data. The UAVs also had to precisely locate and capture high-definition images, automatically identify nearby wind turbines, and either fly around them or adjust altitude for safe operation. Additional tasks included dynamic route optimization, collaborative multi-device obstacle avoidance, accurate target location, and efficient data transmission—thoroughly testing each drone’s endurance, obstacle avoidance intelligence, and data processing ability.

At the competition, the Feima team completed the V10R’s pre-flight preparation faster than other teams, gaining an early advantage. During the task, the V10R, equipped with the TIRV22 video payload, quickly took off from Huachi Airport, flew along a predetermined route to the Nanliang Revolutionary Memorial Hall, and captured images at ten preset coordinates before successfully returning. Thanks to advanced recognition algorithms and high-precision sensors, the V10R accurately identified people and vehicles near the specified locations, completing the challenge with efficiency and precision.

In terms of energy efficiency, the V10R also performed exceptionally well. By optimizing its power system and energy management, it met the demands of high-intensity flight while minimizing consumption. Its energy score, calculated based on takeoff weight, led the field, highlighting its energy-saving advantages. Upon landing, the V10R utilized RTK technology with network connectivity to achieve highly accurate landings, outperforming other drones in the competition.

Creating an “Aerial Recon Expert”: V10R Drone System Powers Smart Oilfield Inspections

Traditional oilfield inspections face numerous challenges: high labor costs, low efficiency, and difficulty covering complex terrain. With the help of low-altitude intelligent flight equipment integrated with 5G, AI, and big data technologies, inspections can now be carried out with greater efficiency, accuracy, and safety.

As a leading UAV company, Feima Robotics has developed the V10R drone platform, which integrates long-range image and data transmission. It supports long-distance video transmission through dual or triple sensor payloads and can be equipped with orthophoto, oblique, and LiDAR payloads for aerial surveying—enabling multipurpose use. Controlled via the “UAV Butler” ground station, it fulfills both video and mapping demands in complex environments.

Altitude Adjustment: Overcoming Terrain Limitations

Operating in complex terrains like mountains, gullies, deserts, and high-altitude regions, the V10R’s variable altitude flight function is a key advantage. In areas with significant elevation changes, it can capture uniformly resolved images or LiDAR data with consistent point density and accuracy—something traditional methods struggle with. With true terrain-following flight capabilities, the V10R flies close to the ground, eliminating inspection blind spots caused by terrain undulations and ensuring comprehensive and accurate data collection.

Powerful Ground Station: Boosting Efficiency and Data Processing

The “UAVManager” ground station system strongly supports V10R’s efficient operations. It features precise 3D flight path planning, allowing teams to quickly design optimal routes tailored to actual oilfield conditions and inspection needs. Real-time 3D flight monitoring enables operators to track position, posture, and flight status, ensuring safety through timely issue detection. Its image processing function handles collected data efficiently. Integrated software modules such as Video App, QualityCheck App, and SmartProcess App enhance processing accuracy.

Video App: Displays the mission interface and real-time video on multiple screens for better field observation.

QualityCheck App: Quickly generates quality reports for improved data inspection.

SmartProcess App: Offers advanced preprocessing for high-precision mapping, enhancing operational and data quality at every stage.

Winning this prestigious award demonstrates Feima Robotics’ innovation and technical strength in the UAV sector, setting a new benchmark for oilfield inspection. Looking ahead, Feima Robotics will continue to embrace innovation, deepen the integration of UAV technology with practical applications, and contribute to building a smarter, more efficient drone ecosystem.